Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

As industries move toward automation and sustainability, Centralized Feeding Systems (CFS) have become a vital solution. In 2025, these systems tackle key challenges like downtime, energy waste, and complex material handling. In this post, we'll explore the latest trends in CFS, highlighting innovations that drive efficiency and sustainability across sectors.

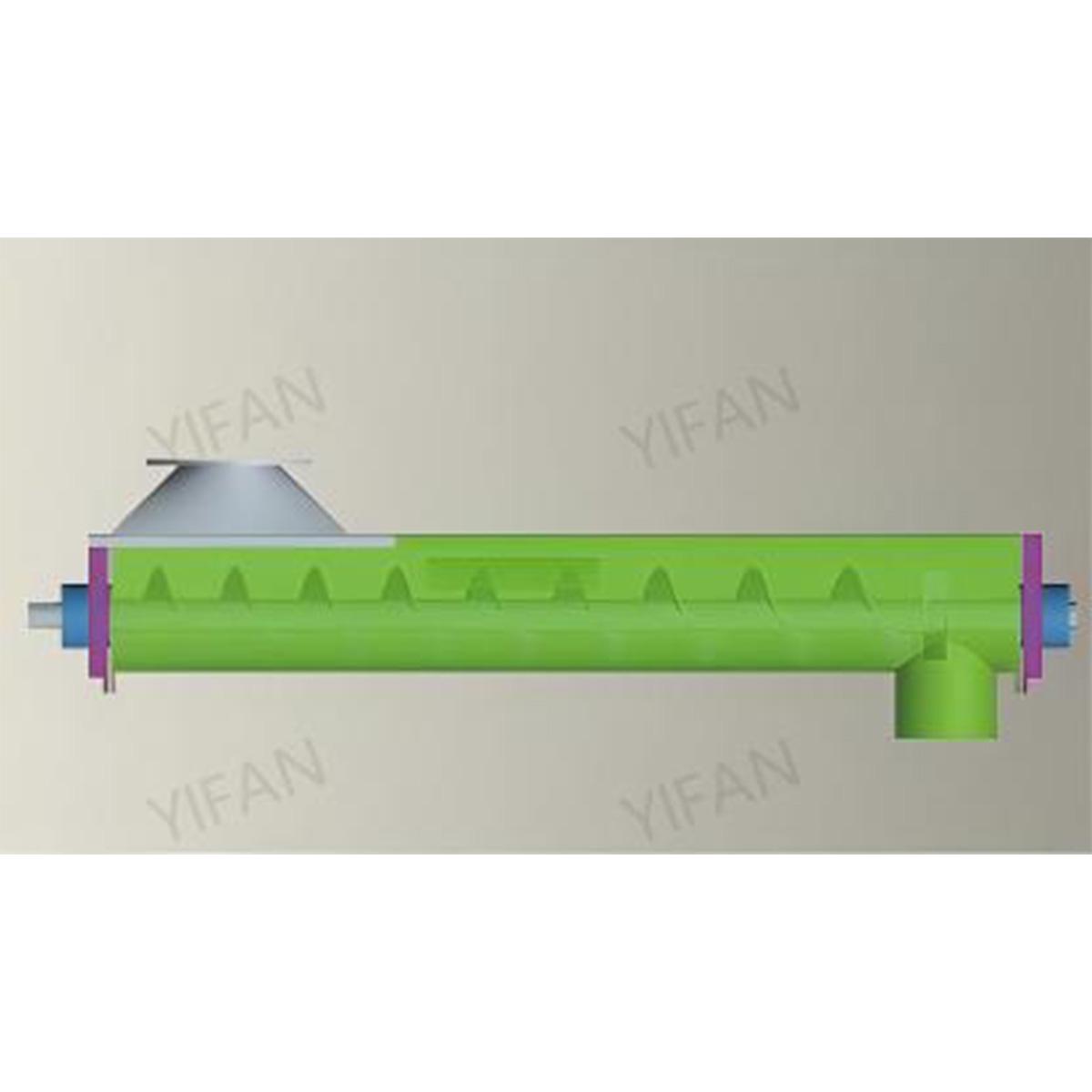

In the plastic manufacturing industry, hybrid conveying systems are becoming increasingly important. These systems combine negative pressure and spiral conveying, providing flexibility in handling a wide range of materials. For example, Jwell Machinery’s PVC Centralized Feeding System integrates these two methods, addressing the diverse needs of plastic manufacturers.

Negative pressure conveying efficiently handles clean, low-abrasion materials like virgin PVC granules. It ensures minimal dust spillage—up to 90% less—by using fully enclosed pipes. On the other hand, spiral conveying is ideal for more abrasive powders, such as CaCO₃-filled PVC, or high-density materials. The 316L stainless steel spirals used in the system are highly resistant to wear, preventing damage to pipes that can cause costly downtime.

The benefits of using hybrid systems in plastic manufacturing are clear. By combining these two modes of conveying, manufacturers can increase efficiency and reduce operational costs. The system’s ability to reduce dust spillage and increase dosing accuracy by up to ±0.2% results in higher-quality products and less waste.

Feature | Benefit |

Negative pressure conveying | Reduces dust spillage by 90% |

Spiral conveying | Prevents pipe damage from abrasives |

Increased dosing accuracy | ±0.2% precision in material dosing |

Aquaculture presents unique challenges when it comes to feeding systems. Hybrid systems, particularly low-pressure pneumatic conveying, are proving to be an effective solution for feeding delicate materials like fish feed. Innovasea and GASC’s Arvo-Tec Centralized Feeding System is an excellent example of how these systems work in the aquaculture industry.

Low-pressure pneumatic conveying operates at a pressure range of 0.2–0.4 MPa, much lower than the typical 0.6–0.8 MPa used in traditional systems. This gentle pressure prevents feed pellet breakage, a common problem in aquaculture that leads to significant waste. The Arvo-Tec system also reduces feed waste by up to 20%, thanks to its ability to adjust feed amounts based on various factors like water temperature and fish size.

This hybrid system is especially valuable in large-scale aquaculture operations, where managing feed efficiency is crucial to maintaining healthy fish stocks and minimizing environmental impact. By preventing breakage and reducing waste, hybrid systems in aquaculture not only enhance production efficiency but also promote sustainability in the industry.

Feature | Benefit |

Low-pressure pneumatic system | Prevents pellet breakage |

Adjustable feed amounts | Reduces feed waste by up to 20% |

Multiple feeding points | Supports up to 28 feeding points per system |

Tip: These hybrid systems provide clear advantages in both the plastic manufacturing and aquaculture industries, offering tailored solutions that address the unique material handling challenges faced by each sector.

Smart automation in centralized feeding systems (CFS) allows for enhanced monitoring and operational efficiency through real-time data. By integrating PLC control and remote app access, manufacturers can track various system metrics, ensuring smooth operations and immediate problem-solving. For example, Xiecheng Machinery’s Central Feeding System in the plastic industry incorporates real-time monitoring of material flow, energy consumption, and temperature, all of which are accessible via a user-friendly mobile app or HMI touchscreen.

This system’s ability to monitor energy consumption is particularly beneficial. With real-time energy tracking, it can highlight inefficiencies and suggest improvements. Operators can also make recipe adjustments instantly, which can lead to faster production cycles and better material consistency. In the long run, these features help reduce waste, improve product quality, and save energy.

Feature | Benefit |

Real-time monitoring | Track energy use, material flow, and temperature |

Remote app control | Instant access to data for quick adjustments |

Recipe switch functionality | Fast adjustments for improved efficiency |

One of the most significant advancements in CFS is the shift from reactive to proactive maintenance. IoT-driven predictive maintenance uses sensors to monitor system health and predict potential failures before they occur. For instance, Chinaplasticsbottles.com’s system in the plastic manufacturing sector uses vibration, pressure, and temperature sensors to detect early signs of wear. When a sensor identifies irregularities, the system sends an alert, allowing operators to take action before a failure happens.

This predictive approach reduces unplanned downtime by up to 60%, ensuring that the system remains operational without unexpected interruptions. It also enhances overall system reliability by identifying maintenance needs before they affect production. This translates to fewer production halts, better resource management, and a more reliable manufacturing process.

Feature | Benefit |

Predictive sensors | Detect potential issues before they occur |

Alerts and notifications | Reduce unplanned downtime by 60% |

Improved reliability | Prevent failures and improve system performance |

By integrating IoT for real-time monitoring and predictive maintenance, manufacturers can ensure smooth, efficient, and cost-effective operations. These technologies help minimize downtime, reduce energy consumption, and enhance the overall functionality of centralized feeding systems.

Modular design has become a key feature in modern Centralized Feeding Systems (CFS), especially in the plastic manufacturing industry. Jwell’s PVC CFS is an excellent example of a scalable system. It allows factories to expand their production capacity without the need for a complete system overhaul. This modular system enables the addition of new silos, pipes, and metering units as needed, all while maintaining compatibility with the existing setup.

For plastic manufacturers, this flexibility is a significant advantage. As production demands grow, they can simply add extra components—whether it's an additional silo or more conveying pipes—without disrupting ongoing operations. This approach not only saves time but also minimizes downtime, ensuring that the factory can continue operating smoothly while expanding.

Feature | Benefit |

Modular silos and pipes | Add extra capacity without replacing the entire system |

Upgradeable metering units | Improve precision as production needs grow |

Scalable design | Expand production seamlessly with minimal downtime |

In the aquaculture industry, managing large-scale feeding operations requires a high level of synchronization. Multi-system synchronization is becoming increasingly important for farms with numerous tanks. Innovasea’s Arvo-Tec systems provide a great solution for large aquaculture farms by allowing multiple systems to operate in harmony. This synchronization ensures that farms can scale efficiently from managing 100,000 fish to over 1 million.

With this system, farm operators can control and monitor multiple feeding points via a single interface. This integration allows for more efficient resource management, reducing labor costs and improving feeding accuracy. It also provides a streamlined way to scale operations as demand increases, ensuring that feed is distributed evenly and effectively across the farm.

Feature | Benefit |

Multi-system synchronization | Manage multiple feeding systems from one interface |

Scalable operations | Efficiently scale from 100,000 to 1 million fish |

Integrated control | Streamlines farm management and reduces labor costs |

The modular and scalable design of these systems ensures that factories and aquaculture operations can adapt quickly to growing production demands without significant disruptions. These flexible systems not only enhance efficiency but also support long-term growth and sustainability.

As industries focus more on sustainability, energy efficiency and waste reduction are becoming key factors in designing Centralized Feeding Systems (CFS). One of the most effective ways to achieve this is through energy-saving technologies such as heat recovery and low-pressure conveying systems. These technologies reduce energy consumption by capturing and reusing heat that would otherwise be wasted, and by using lower pressure systems to move materials efficiently.

For example, Innovasea’s energy-efficient systems in aquaculture utilize low-pressure pneumatic conveying, which uses up to 50% less energy than traditional high-pressure systems. This not only reduces the carbon footprint but also lowers operational costs. By implementing heat recovery, Innovasea has also been able to reduce energy use by 30%, improving both economic and environmental performance.

Feature | Benefit |

Low-pressure conveying | Reduces energy use by up to 50% |

Heat recovery technology | Cuts energy consumption by 30% |

Energy-efficient systems | Lowers operational costs and carbon emissions |

Another important aspect of sustainable CFS designs is the use of dust-free systems and recyclable materials. Many modern CFS incorporate closed-loop systems that prevent dust spillage, reducing environmental hazards in industries like plastic manufacturing. Additionally, recyclable components in the system itself ensure that materials are reused, minimizing waste.

Jwell’s PVC Centralized Feeding System is a prime example of such sustainable practices. Their system uses closed-loop conveying and cyclone dust collectors, which eliminate 95% of dust spillage. This reduces pollution and enhances worker safety. Moreover, Jwell's design includes modular and recyclable components, ensuring that the system can be easily upgraded or replaced without contributing to e-waste.

Feature | Benefit |

Closed-loop systems | Prevents dust spillage, reducing pollution |

Cyclone dust collectors | Improves air quality and reduces health risks |

Recyclable modular components | Reduces e-waste and supports system upgrades |

By integrating energy-saving technologies and promoting recyclable, dust-free designs, modern CFS systems are playing a vital role in reducing environmental impact while improving operational efficiency. These features not only help companies meet sustainability goals but also provide long-term cost savings.

The shift toward unmanned operations in plastic manufacturing is revolutionizing the industry. Lights-out production refers to fully automated factories that can operate 24/7 without human intervention. Xiecheng Machinery’s integration of manipulators and granulators with their centralized feeding system demonstrates this concept. This system handles raw materials, processes them, and even manages production lines automatically, ensuring continuous operation.

By using advanced robotics and automated systems, plastic factories can run around the clock, leading to a significant increase in production output. In fact, Xiecheng’s system has resulted in a 30% increase in output, as it eliminates the need for manual labor during off-hours. Additionally, this approach reduces labor costs and minimizes the risk of human error, making production more efficient and reliable.

Feature | Benefit |

Integration with manipulators | Full automation for 24/7 production |

Granulators for recycling | Increases output by 30%, reduces downtime |

No human intervention | Reduces labor costs and human error |

Remote management is also transforming the aquaculture industry, particularly with systems that allow for remote feed adjustments. GASC’s Arvo-Tec Centralized Feeding System offers remote access features, enabling aquaculture farmers to monitor and adjust feeding schedules from anywhere, at any time. This technology ensures that feed is administered according to the fish’s needs, without requiring physical presence on the farm.

With the ability to remotely adjust feed levels, farmers can ensure optimal fish health, improve feed efficiency, and reduce waste. For example, if water temperature drops or the fish are less active, the system can automatically adjust the feed dosage. This not only improves the overall health of the fish but also increases efficiency by ensuring feed is not overused.

Feature | Benefit |

Remote access to feeding systems | Allows farmers to monitor and adjust remotely |

Adjustable feed schedules | Ensures optimal fish health and reduces waste |

Automated adjustments | Enhances feed efficiency and reduces manual labor |

By enabling unmanned operations in both plastic manufacturing and aquaculture, these systems optimize production and reduce reliance on human intervention. This automation enhances efficiency, reduces costs, and ensures continuous operations, ultimately contributing to the growth and success of businesses in these industries.

The future of centralized feeding systems (CFS) is heavily influenced by the integration of IoT and modular designs. As industries grow and evolve, the need for scalable and flexible systems becomes more critical. IoT technology enables real-time monitoring and remote control, allowing manufacturers to optimize their operations efficiently. With IoT-enabled systems, data on material flow, energy consumption, and operational performance is collected and analyzed, ensuring adjustments can be made quickly.

Modular designs complement IoT by offering the flexibility to expand systems as production needs change. Whether adding new silos, increasing storage capacity, or integrating new production lines, modular CFS designs make it easier to scale operations without a complete overhaul. This combination of IoT and modular solutions ensures long-term sustainability, reduced operational costs, and the ability to keep up with evolving industry demands.

Feature | Benefit |

IoT-enabled monitoring | Real-time adjustments to improve efficiency |

Modular design flexibility | Scalable system expansions without overhauls |

Data-driven insights | Helps reduce costs, improve sustainability |

Artificial Intelligence (AI) is transforming predictive maintenance in CFS, enhancing their ability to foresee and prevent failures before they occur. AI analyzes data from various sensors embedded in the system, learning patterns and identifying potential issues that could lead to downtime. By incorporating machine learning algorithms, AI can detect anomalies such as unusual vibration, temperature fluctuations, or pressure drops, which signal equipment wear or failure.

This proactive approach to maintenance helps businesses reduce unplanned downtime by allowing them to perform repairs before major breakdowns happen. AI also improves the accuracy of maintenance schedules, extending the life of CFS and reducing operational costs. In industries where constant production is essential, AI-driven predictive maintenance offers a significant competitive advantage.

Feature | Benefit |

AI-driven predictive maintenance | Reduces downtime by identifying issues early |

Machine learning algorithms | Improves accuracy in maintenance scheduling |

Sensor data analysis | Enhances system reliability and longevity |

With the integration of IoT, modular designs, and AI, centralized feeding systems are becoming more adaptable and efficient. These cutting-edge trends not only help future-proof operations but also offer significant cost savings, improved efficiency, and enhanced reliability in the long run.

The latest trends in Centralized Feeding Systems (CFS) for 2025 include hybrid conveying, smart automation, modular design, sustainability, and unmanned operations. These innovations are tailored to meet the future needs of industries like plastic manufacturing and aquaculture. By embracing these trends, companies can enhance operational efficiency, reduce costs, and ensure long-term sustainability. Companies like Yifan offer cutting-edge solutions that align with these trends, providing scalable and efficient systems that support growth and sustainability. Investing in these advancements will future-proof operations and boost overall productivity.

A: A Centralized Feeding System (CFS) is an automated system used in industries like plastic manufacturing and aquaculture to handle material feeding efficiently. It reduces downtime, improves accuracy, and increases productivity.

A: Hybrid conveying systems combine different material transport methods, such as negative pressure and spiral conveying, enhancing the efficiency of CFS by reducing dust spillage and increasing dosing accuracy.

A: Sustainability in CFS focuses on energy efficiency, waste reduction, and the use of recyclable materials. This helps reduce environmental impact, lower operational costs, and promote long-term sustainability.

A: IoT integration allows real-time monitoring and predictive maintenance in CFS, improving operational efficiency and reducing downtime by offering actionable insights into system performance.