Views: 0 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

A centralized feeding system is a modern solution used in industries like plastics, aquaculture, and food processing. It automates material handling, reducing manual labor and improving consistency. By centralizing control, it ensures better quality and efficiency across production lines. In this post, we'll explore how it works and why it's essential for modern manufacturing processes.

A centralized feeding system is a fully automated solution designed to streamline the material handling process across various industries. The key feature is centralized control, which integrates the management of material storage, transport, and distribution from a single point. This setup reduces human intervention and manual labor, ensuring that the flow of materials is consistent and efficient. Additionally, the system is modular, with components tailored to specific industries, such as plastics, aquaculture, or food processing, making it adaptable to different needs.

Centralized feeding systems are widely used in several industries where material handling is essential. In plastics manufacturing, these systems are used to manage the storage and delivery of raw materials like plastic granules to multiple production lines. The system ensures precise dosing, drying, and dehumidification, which is crucial for maintaining high-quality standards in plastic parts production.

In aquaculture, a centralized feeding system is used to distribute fish feed to multiple tanks or cages. The system allows feed to be stored in large silos and then transported via air or water pipes to specific locations. This ensures that the fish receive a consistent amount of feed without the need for manual labor, which can be time-consuming and prone to error.

The chemical industry also benefits from centralized feeding systems, especially in the handling of powders and granules like cement or other bulk materials. Pneumatic conveying systems, a key feature of centralized feeding setups, help move materials through long distances and multiple production stages without contamination. Similarly, in food processing, the system is used to transport ingredients like flour or sugar to different production stations, ensuring cleanliness and accuracy.

In a decentralized feeding system, each machine or production line has its own storage and material handling equipment. This requires more manual effort to manage each unit, leading to inefficiencies in terms of labor and time. It can also result in higher material waste, as separate storage systems may not be optimized for all production lines.

On the other hand, a centralized feeding system consolidates all material handling processes into one controlled system. By automating the transportation of materials, it reduces human error, improves the flow of materials, and decreases labor costs. The centralized system also ensures that raw materials are consistently delivered to each production line, eliminating the variability that can occur in decentralized systems. This setup leads to better quality control, as the material flow is more easily monitored and adjusted from a central control station.

Feature | Centralized Feeding System | Decentralized Feeding System |

Control | Centralized control | Individual controls for each machine |

Material Handling | Automated, integrated | Manual or semi-automated |

Efficiency | High, reduces downtime | Lower, more prone to errors |

Labor Requirements | Reduced, minimal intervention | High, requires more personnel |

Consistency of Material Flow | Consistent and monitored | Variable, can lead to waste |

The central control station serves as the heart of a centralized feeding system. It uses programmable logic controllers (PLC) or modular automation to monitor and regulate the flow of materials throughout the system. This control center ensures that materials are distributed efficiently and in the right quantities, reducing the risk of overfeeding or shortages. It tracks the status of each component, including conveyors, storage units, and processing equipment, providing real-time data for seamless operation.

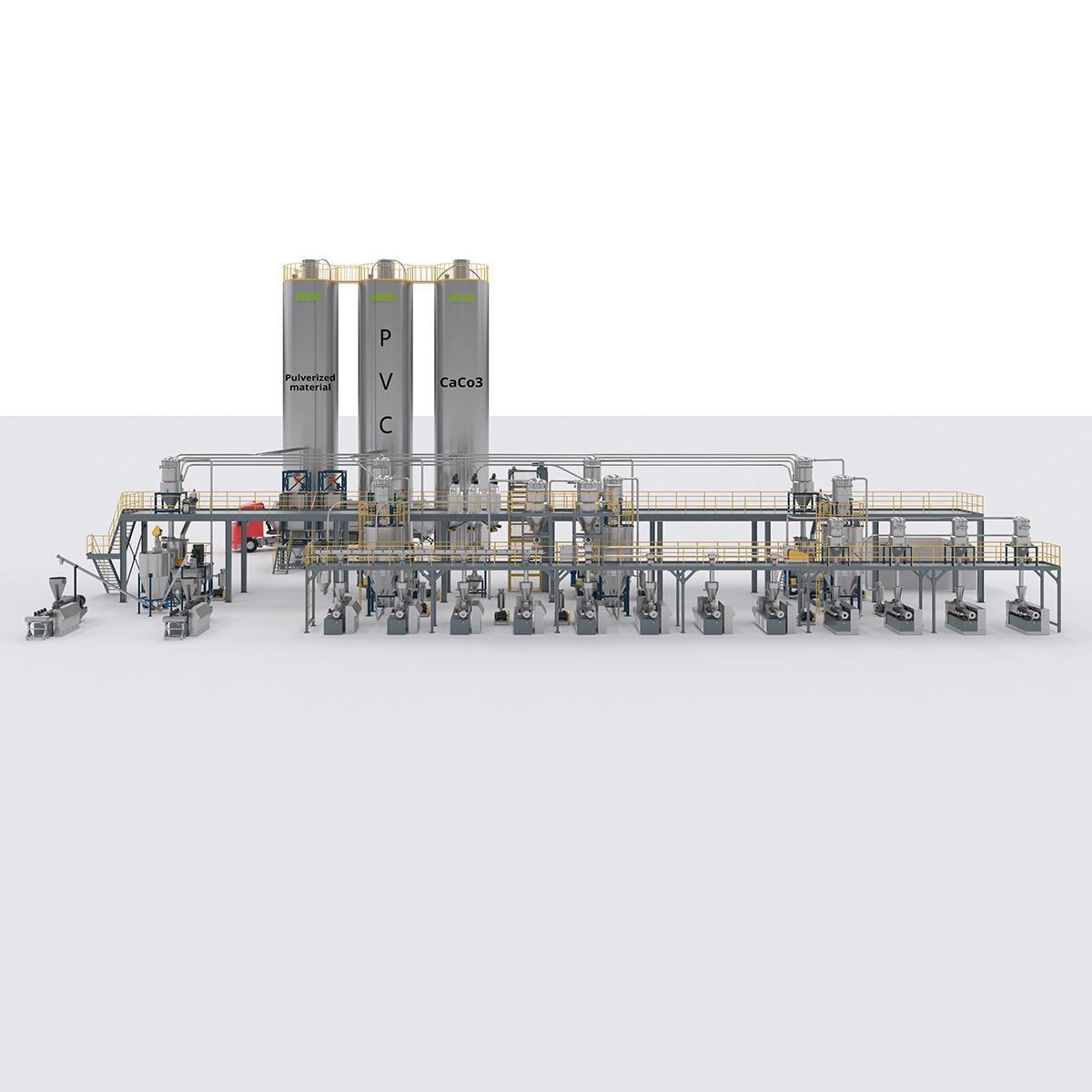

Material storage units, such as silos and hoppers, are crucial for holding raw materials before they are processed or transported. These units are designed to maintain a continuous supply of materials, preventing production delays. Silos are typically used for bulk storage, especially in industries like plastics or chemicals, where large quantities of granules or powders are required. Hoppers, on the other hand, are often used to store smaller quantities of materials and feed them into the system for further processing or delivery.

The conveying system is responsible for transporting materials from one point to another within the feeding system. It can utilize pneumatic or mechanical methods depending on the material type and distance. Pneumatic conveying uses air pressure to move lightweight materials like powders or granules through pipes, while mechanical conveying uses screw conveyors or belts to transport heavier or denser materials. Both systems are designed to minimize material loss, reduce contamination, and ensure the smooth flow of materials to production units.

Processing modules play a key role in preparing materials before they are delivered to production lines. These modules include drying, dosing, and mixing components, which ensure that materials meet the required specifications. For example, in plastics production, drying units remove moisture from raw materials, preventing defects during molding. Dosing systems accurately measure additives or colorants, ensuring that the correct ratios are used. Mixing modules blend different ingredients to create a uniform mixture, which is essential for maintaining quality control.

Component | Function | Industry Application Example |

Central Control Station | Monitors material flow, adjusts speed, triggers alarms | Plastics: Controls injection molding machines |

Material Storage Units | Stores raw materials (silos, hoppers) | Aquaculture: Silo for fish feed storage |

Conveying System | Moves materials via air or mechanical conveyors | Chemical: Pneumatic pipes for transporting powders |

Processing Modules | Prepares materials (drying, dosing, mixing) | Food: Online mixers for ingredient preparation |

Tip: The design of each component plays a vital role in ensuring that the system operates efficiently and effectively across various industries.

The first stage in a centralized feeding system involves preparing and storing raw materials. In the plastics industry, for instance, plastic granules are stored in large silos, ensuring a steady supply for production. These materials are then sent to drying units, where moisture is removed to prevent defects during molding. In aquaculture, fish feed is loaded into onshore or barge-mounted silos before being transported to tanks or cages. These storage units are designed to keep materials readily available for continuous production.

Once materials are prepared, they need to be conveyed to various production units. This is done through either pneumatic or mechanical conveying methods. Pneumatic conveying uses air pressure to move lightweight materials, such as powders or granules, through pipes. It is ideal for long-distance transportation. On the other hand, mechanical conveying, such as screw conveyors, is used for heavier materials. This method is more suitable for dense or wet substances, ensuring that materials are transported without separation or loss.

After conveying, materials are distributed to specific production units through a central coupling or distribution station. Proportional valves and selector valves play a critical role here. In the plastics industry, these valves regulate the flow of materials to different molding machines based on their specific needs. Similarly, in aquaculture, selector valves direct feed to the appropriate tanks or cages. This precise distribution ensures that each production line or unit receives the correct amount of material, optimizing efficiency.

Real-time monitoring is essential for the smooth operation of a centralized feeding system. The central control station tracks key parameters like material levels, conveyor speed, and filter status. If a pipe clogs or a silo runs low on material, the system automatically triggers alarms. In addition, contamination control measures, such as filtration systems, are in place to prevent dust, moisture, or foreign particles from entering the materials. This ensures consistent material quality and protects both the system and the final product from contamination.

Stage | Description | Industry Example |

Material Preparation & Storage | Raw materials are stored in silos, prepared for transport | Plastics: Silos for plastic granules |

Conveying Materials | Pneumatic or mechanical methods transport materials | Aquaculture: Air or water pipes for feed |

Distribution to Units | Valves direct materials to production lines | Plastics: Proportional valves for molding machines |

Monitoring & Protection | Real-time control and contamination prevention | Food: Dust filters and sensor systems |

A major benefit of a centralized feeding system is its ability to significantly reduce labor requirements. By automating the process of material handling, the system minimizes the need for manual labor across production lines. Reports from industries like plastics manufacturing show that automated systems can cut labor costs by up to 66%. This allows companies to reallocate their workforce to other critical areas, improving overall productivity. In addition to labor savings, automation also reduces the chances of human error, leading to fewer production delays and defects.

Centralized feeding systems ensure the consistent quality of materials, an essential factor in industries where precision is critical. For example, in plastic manufacturing, controlling the moisture level in materials is crucial to prevent defects during the molding process. The automated control of material flow reduces the risk of contamination from foreign particles and ensures that raw materials, such as plastic granules or powders, are handled under optimal conditions. In aquaculture, centralized systems maintain the integrity of fish feed by keeping it free from contaminants and moisture, resulting in consistent feeding quality.

Centralizing equipment, such as dryers and silos, reduces the amount of space needed for material storage and handling. This is particularly valuable in industries with limited factory space. By consolidating these functions into a single area, businesses can free up valuable floor space for other operations. Additionally, centralizing processes like drying helps save energy. For example, shared drying equipment can reduce energy use by up to 40% compared to using individual dryers for each production line. This not only lowers operating costs but also contributes to sustainability efforts by reducing energy consumption.

Advantage | Description | Industry Example |

Reduced Labor and Costs | Automation cuts labor costs and increases productivity | Plastics: 66% fewer workers needed |

Consistent Material Quality | Prevents contamination and maintains optimal material conditions | Aquaculture: Prevents moisture in fish feed |

Space and Energy Efficiency | Saves space and reduces energy consumption | Food Processing: Centralized drying units |

Centralized feeding systems can encounter several issues during operation. One of the most common problems is clogging. This typically occurs when materials, such as powders or granules, accumulate in pipes, causing blockages that slow down or stop the system. To resolve this, regular inspections and cleaning cycles are essential. Another issue is material shortages, which can happen if the system is not properly calibrated or if storage units run low on material. Installing level sensors and setting up automated alerts can prevent this from disrupting production. Lastly, system faults, such as malfunctioning valves or conveyor breakdowns, can occur. Regularly testing components like valves and conveyor belts, along with having backup systems in place, helps address these issues promptly.

Proper maintenance is crucial to keeping a centralized feeding system running smoothly. One important task is pipe purging. This involves clearing any residual material left in the pipes after each production run, which helps prevent cross-contamination between batches. Additionally, filter checks are vital. Filters, such as ventilation filters and dust collectors, should be inspected and cleaned regularly to prevent clogging and maintain optimal air quality. Another key maintenance task is checking the system's sensors and control station. Ensuring that sensors are calibrated correctly guarantees accurate material flow and reduces the risk of errors. Routine inspections, along with scheduled cleaning and component checks, will ensure the longevity and efficiency of the system.

Tip: To prevent material loss and ensure consistent quality, keep an eye on material levels and automate alerts when storage units are running low.

A centralized feeding system plays a crucial role in improving efficiency, reducing labor costs, and ensuring consistent product quality. By automating material handling, it eliminates manual processes and minimizes errors. Companies like Yifan offer advanced systems tailored to industry needs, enhancing operational performance. For businesses looking to optimize their production, upgrading to a centralized feeding system is a smart investment for long-term success.

A: A centralized feeding system is an automated setup that streamlines material storage, transport, and distribution to various production units, improving efficiency and reducing costs.

A: The system works by using conveyors and sensors to move materials from storage units to production lines, ensuring consistent material flow and minimizing manual labor.

A: Upgrading to a centralized feeding system reduces labor, enhances efficiency, and improves product quality, ultimately leading to better operational outcomes.